Precautions for Piping Installation

Precautions for Piping Installation

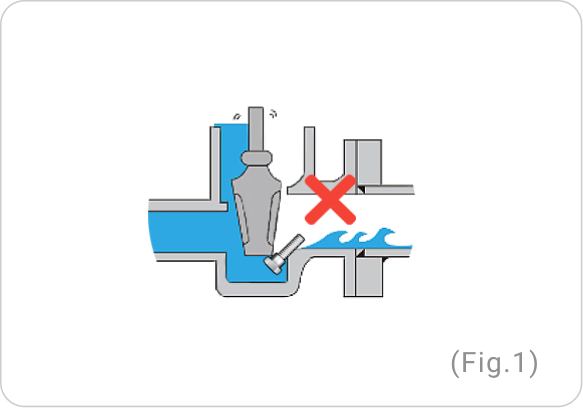

1. Before installing the pipes, inspect the valves for debris and oil stains. If any are found, they should be removed first. Debris is a common cause of water leakage and can damage the valve and obstruct the flow, which may require the valve to be replaced with a new one. (Fig.1)

2. When locking the pipe end to the threads of the valve inlet and outlet, be careful not to over-tighten it, which may cause impact on the outer edge of the water inlet, leading to deformation or damage to the valve, and even result in the phenomenon of valve body squeezing and cracking.

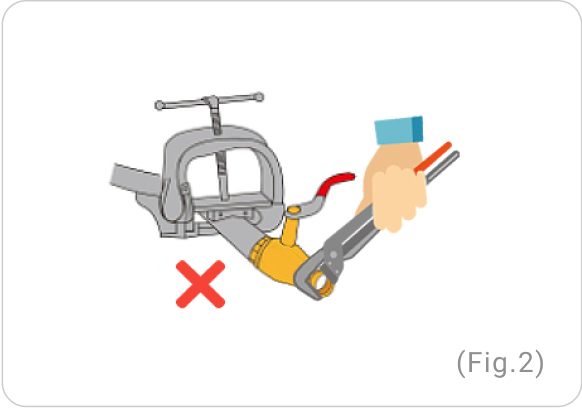

3. When installing pipes, the pipe fittings should be clamped with a fixture, and a pipe wrench should be used to grip the hexagonal part of the valve for locking and installation. Do not clamp the valve with the pipe wrench and rotate the pipe fittings for locking and installation.

4. When performing valve installation and locking operations for piping, the position where the pipe wrench grips the hexagonal part of the valve should be close to the end of the pipe fitting, and not far away from it. (Fig.2)

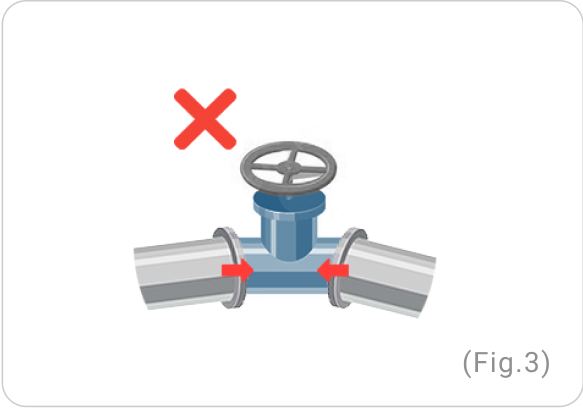

5. The center points of the two flanges at the pipe end should be accurate, and the two flange faces should be configured in parallel. Piping should not be performed when there is an angle or when the flange faces are uneven. (Fig.3)

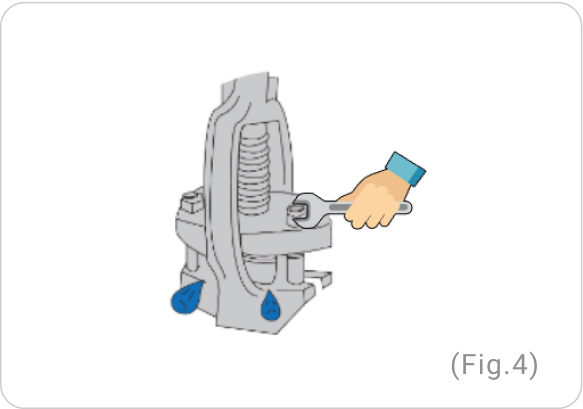

6. The burrs on the inner and outer corners of the flange faces should be removed and chamfered before piping.(Fig.4)

7. When the valve stem is leaking, gradually tightening the valve bonnet screws can stop the leakage.

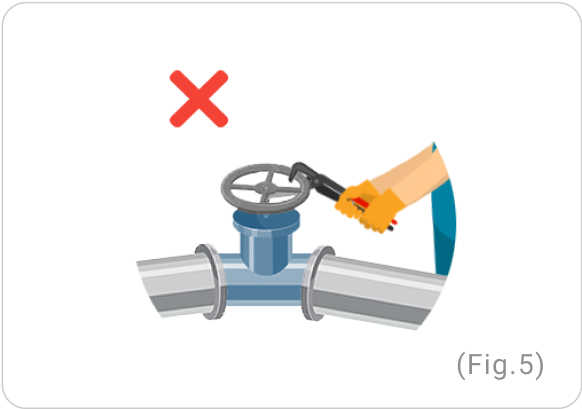

8. After piping, if there is a slight leak during testing, the valve should be opened first, debris should be cleared, and then the valve should be closed. The valve should not be forcibly tightened with a lever. (Fig.5)

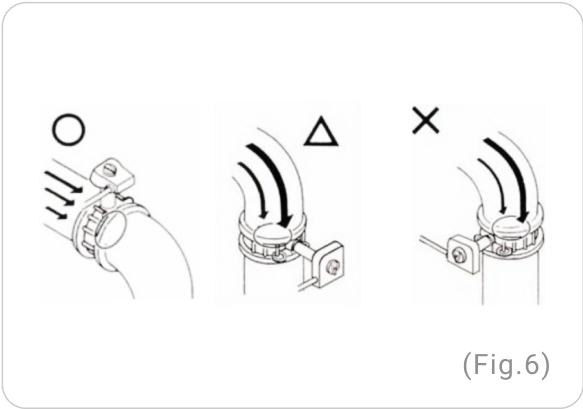

9. When assembling butterfly valves and dual plate check valves, if the water inlet is a curved pipe and there is a pressure difference shock inside the pipe, the position of the valve stem should be placed in the direction of the pressure difference to prevent flow-blocking leaf damage from uneven wear and unstable positioning caused by the pressure difference. If the water outlet is a curved pipe, then the position of the valve stem should be placed at a 90 degree angle direction from the direction of the pressure difference to reduce pressure drop.(Fig.6)

10. When tightening the fixed flange, it should be gradually tightened in a diagonal and 90 degree diagonal sequence. Adjacent tightening sequences should be avoided, and it is also not advisable to lock it completely at the beginning of the tightening process.

合鑫閥業由經驗豐富的閥類設計、製造和銷售專業人士組成。我們憑藉市場通路和客戶需求的了解,通過專業創新和研發投入,期待為閥類傳統產業注入新血,並通過品牌策略、產品定位,締造永續的核心價值。

地址:台灣新北市淡水區崁頂57-12號

Copyright © 2023 Ho-Hsin All Rights Reserved.

Ho-hsin Valve Industry is composed of experienced professionals specializing in valve design, manufacturing, and sales. With our understanding of market channels and customer needs, we strive to inject new vitality into the traditional valve industry through professional innovation and research and development efforts. We aim to create sustainable core value through brand strategies and product positioning.

Product

Application

Address:NO57-12,KANDING,TAMSUI DIST.,NEWTAIPEI CITY 25172 TAIWAN(R.O.C)

Copyright © 2023 Ho-Hsin All Rights Reserved.